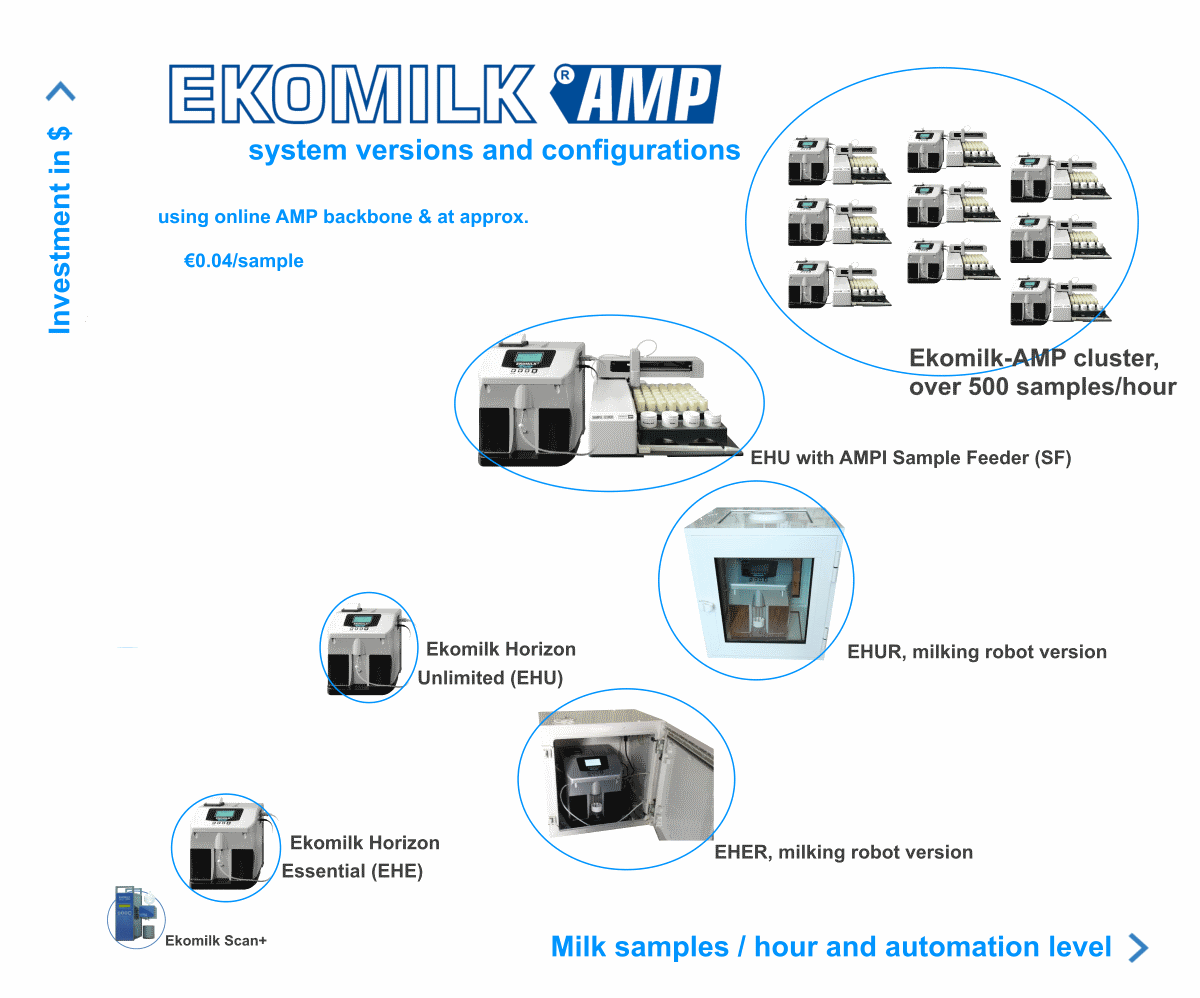

Overview specifications of the Ekomilk-AMP system with Ekomilk Horizon and optional Sample Feeder. EHE, EHER, EHU, EHUR, SF, AMP.

Every Ekomilk-AMP system includes an online AMP admin account, for automatic dashboards and visualisations, emails with XLS or CSV result reports, notifications and/or measurement results over SMS, instrument calibration, various milk sample identification workflows with or without barcode or RFID reader, maintenance and remote support besides optional Cloud APIs for automatic data exchange.

It is recommended to start with either the Mini-lab or with Ekomilk Horizon Unlimited (EHU). An AMP admin account is always included.The most basic version of the Ekomilk-AMP system consists of Ekomilk Horizon Essential (EHE) with of course an AMP account. Ekomilk Horizon Essential (EHE) counts somatic cells (SCC) in milk. For best accuracy results, ICAR-compliant milk samples are recommended. Ekomilk Horizon Unlimited (EHU) with AMP will usually detect and warn if sampling errors (non ICAR compliant?) or sample preparation errors (mixing? clots?) are made. Also the cleaning process is monitored in greater detail, leading to a longer instrument life and less chances to break warranty conditions. That's why it's better to start either with EHU or the Mini-lab, instead of EHE. EHE is a great tool for individual (per cow) udder health, subclinical mastitis detection and milk quality monitoring but EHE lacks the advanced error diagnosis features of EHU and Mini-lab.

It is recommended to start with either the Mini-lab or with Ekomilk Horizon Unlimited (EHU). An AMP admin account is always included.The most basic version of the Ekomilk-AMP system consists of Ekomilk Horizon Essential (EHE) with of course an AMP account. Ekomilk Horizon Essential (EHE) counts somatic cells (SCC) in milk. For best accuracy results, ICAR-compliant milk samples are recommended. Ekomilk Horizon Unlimited (EHU) with AMP will usually detect and warn if sampling errors (non ICAR compliant?) or sample preparation errors (mixing? clots?) are made. Also the cleaning process is monitored in greater detail, leading to a longer instrument life and less chances to break warranty conditions. That's why it's better to start either with EHU or the Mini-lab, instead of EHE. EHE is a great tool for individual (per cow) udder health, subclinical mastitis detection and milk quality monitoring but EHE lacks the advanced error diagnosis features of EHU and Mini-lab.

Moreover, EHU and the Mini-lab increase the SCC measurement accuracy and reliability. EHU measures milk fat content, milk protein content, milk total solids content and somatic cells (SCC) in milk, besides optionally lactose, added water and ketosis risk indicator.

On-field accuracy examples of the Ekomilk AMP system installed on European dairy farms for real-time somatic cell count (SCC), milk fat content F, milk protein content P in 2017 _ draft.pdf

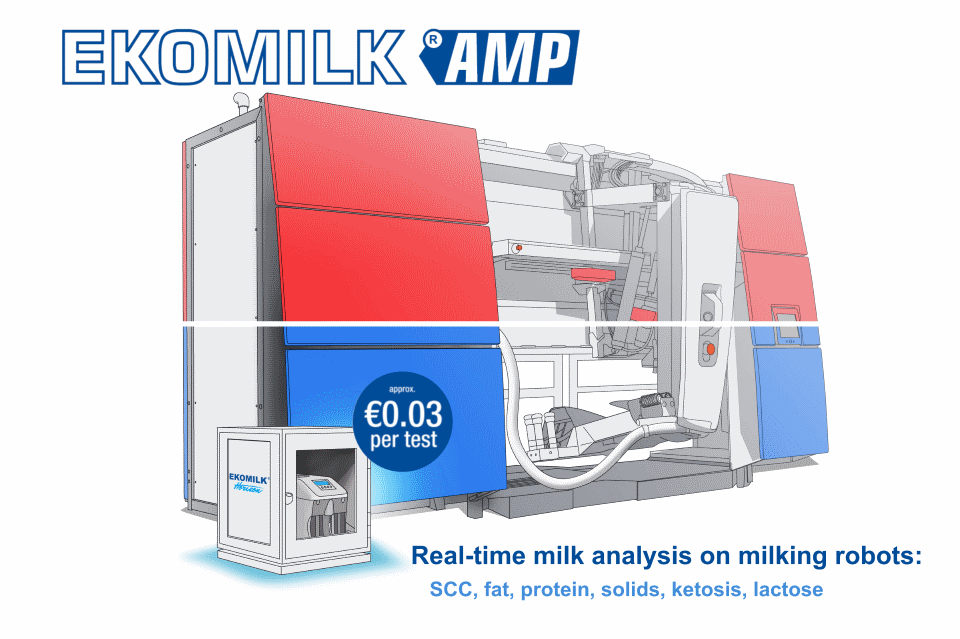

For both Ekomilk Horizon Essential (EHE) and Ekomilk Horizon Unlimited (EHU), a special version exists for direct connection to milking robots (robotic milking). Abbreviated this becomes EHER and EHUR. No need for a Shuttle or ORI collector anymore thanks to EHER and EHUR.

Milking robots (AMS, VMS, robotic milking)

Milking robots (AMS, VMS, robotic milking)

To avoid the most common measurement mistakes which lead to lower accuracy and reduced system reliability, a AMPI Sample Feeder (SF) can be added to Ekomilk Horizon Unlimited (EHU) so you have a "Mini-lab", "milk lab", or "Minilaboratorium for milk quality and cow health analysis". With the Minilab, sample loading, preparation, verification and sample supply is automated. Cleaning and rinsing are also greatly automated so the chance to forget rinsing at the end of the working day (and potentiallty damage the system and lose warranty) is reduced. The Ekomilk-AMP Mini-lab is instance popular in conventionnal milking parlors and in laboratoties (labs) or even vans (small trucks) for instant analysis of over 400 dairy cows within 1 day (on-farm).

The "most common mistakes" which are made without Sample Feeder, are the sampling (non-ICAR compliant, manual cow sampling or not mixing the bulk milk tank enough) and the sample preparation (not mixin correctly before measuring, either introducing air bubbles or mixing too long beforehand).

Mini-lab intro video (Sample Feeder and Ekomilk Horizon)

With the Mini Milk Lab, you have an on-farm point of analysis which allows to accurately analyse bulk tank, individual composite and quarter milk samples. No need for frequent sample transportation to a central milk quality lab.

You can use the default sample trays of 49 milk samples and the service rack for system verification, cleaning and rinsing. No need for an operator to stay near the mini milklab system, system warnings can be followed online or even email (and optionally SMS).

For high sample throughput, an Ekomilk-AMP cluster combines several sample loading stations are operating in parallel, autonomously. The lab operator only has to refill water and reagents as indicated by the AMP cluster backbone system.

Ekomilk-AMP cluster introduction for achieving 350 milk samples per hour with a single laboratory operator at approx €0.04/test

Overview of Ekomilk-AMP system configurations with peripherals, accessories, workflow automation and integration options: